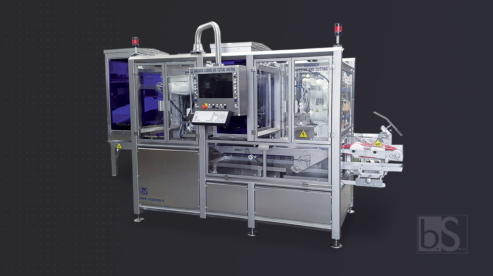

PICK & PLACE

2P ROBOT

B.S. has designed the 2P Robot PICK and PLACE to deposit portions of sliced meats and cheese into tray in a complete automatic way.

The machine is specifically designed to be positioned and installed, with autonomous supports, above the thermoforming machine, to deposit the portions in the trays of destination, which advance directly on the thermoforming machine.

Productivity: The 2P ROBOT productivity depends on product type , on portion to realize and on tray size, reaching maximum performances of about 50-55 deposits/min.

details

Features

Format-changes are rapid and minimized to the replacement of the only gripping head related to the processed product and to the tray size. The recipes are different for the number and placement of deposits, since it is possible to achieve multiple deposits with a single load.

Flexibility

The 2P ROBOT is studied to guarantee maximum versatility and flexibility during production. In fact the 2P ROBOT is able to work with all type of sliced product maintaining high deposit precision.

Memory for recipes

The deposit recipes created can be stored. The machine is in fact equipped with memory to save settings and specific recipes for each sliced portion and for each type of deposit, to recharge and reprogram in future.

Vision System

The sliced portions can arrive from the slicer not perfectly aligned with the advancement direction of the conveyor belt, so a specific vision system allows perfect loads and deposits. The device reads the portion position and sends the input signal for positioning exactly the gripping head.

Specifications

The 2P ROBOT is a machine of reduced dimensions compared to its functions. Directly with keyboard and touchpad it is possible to manage the operator panel which controls the machine, that can also be controlled remotely for loading new settings.

Reduced dimensions

Touchpad Panel

Remote Control

How it works

The operation of the machine is divided into three phases: recognition, loading and deposit. The product, deposited on the conveyor belts directly from the slicer and already portioned in the number of desired slices, is conveyed into the robot vision area. After the reading of the signal, the 2P ROBOT arm starts to work. Before the gripping head, designed and realized completely by B.S., is conduct to align perfectly with the slices portion and then starts to execute the loading operation. To complete, speed up and increase performances during production phases, B.S. is able to provide specific accumulation and scrap buffers: interposed between slicer and robot to directly dialogue with both operator machines. Their advantage is to greatly reduce the production downtime for product recharge.

Cleaning and Materials

The machine design consents complete cleaning and sanitizing phases, moreover in quick and effective way. Furthermore some particular devices permit the direct access to the cargo area of thermoforming machine during these cleaning phases. The 2P ROBOT is completely made of continuous welded 304 stainless steel and food approved plastics materials, and is CE compliant.